Which materials for sustainable packaging?

When discussing sustainable packaging, the choice of material is often one of the first question asked. And in the age of environmental awareness, conscious consumers and engaged brands tend to incline towards material that have a green image like paper or glass. But the reality is that it’s not that simple and clearcut.

Materials chosen for packaging indeed play a crucial role in the sustainability of the solution – however many other considerations must be taken into account. So, to the question “what material should I select?” the answer is always “it depends.”

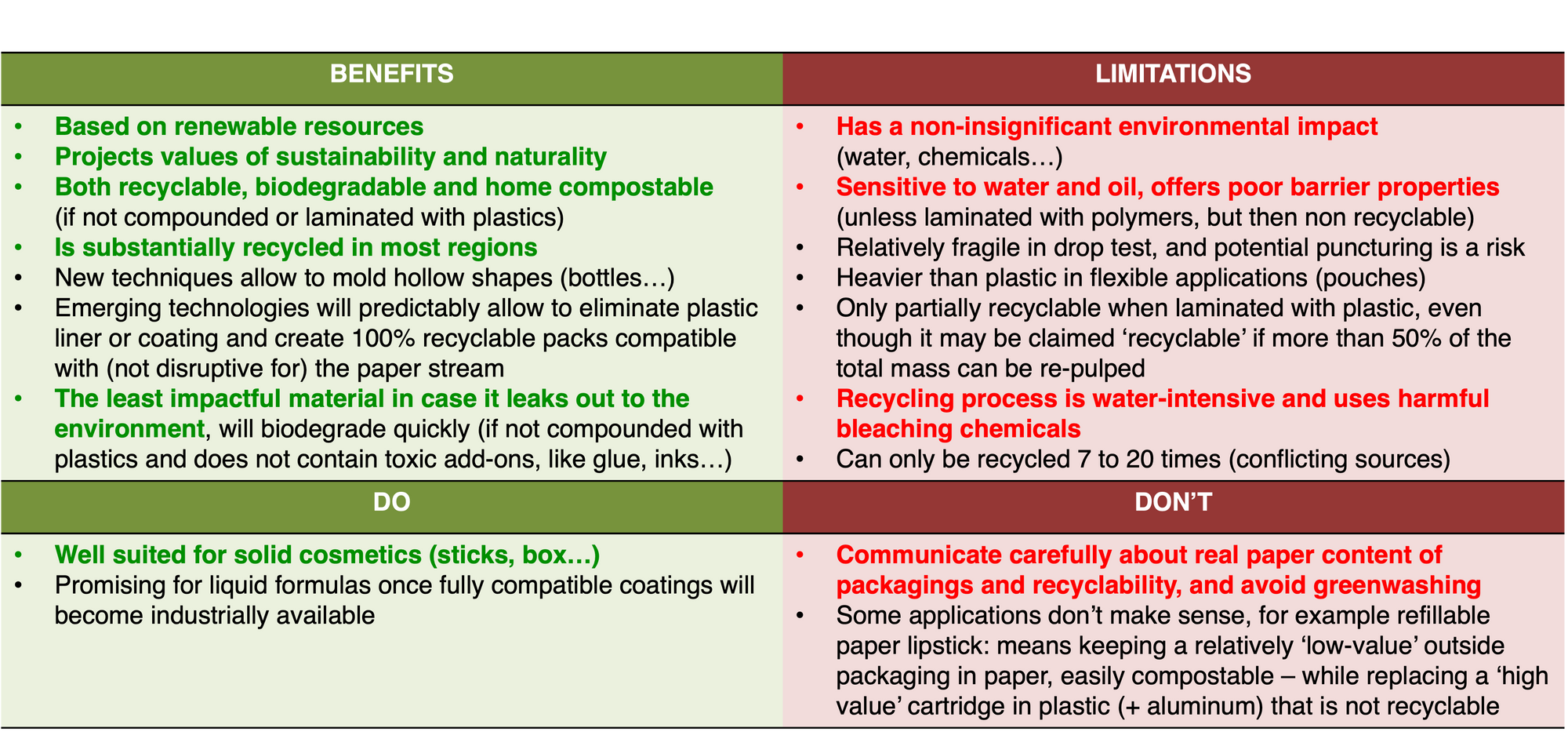

Here we try to provide a synthetic view of the benefits and limitations of the most used packaging materials, and of their recommended / not recommended uses.

Spoiler alert 1: there is no ‘good’ or ‘bad’ material, all materials have their benefits and their limitations, and it’s all about what material is used for what purpose.

Spoiler alert 2: there is no silver bullet either, a ‘magical material’ that would solve all needs! Each choice comes with a ‘price to pay’, and the role of brands is to make informed arbitrations towards a balanced solution, in coherence with the brand’s values and philosophy – and to communicate in a transparent and honest way about those choices.

Packaging materials benchmark

BENEFITS AND LIMITATIONS

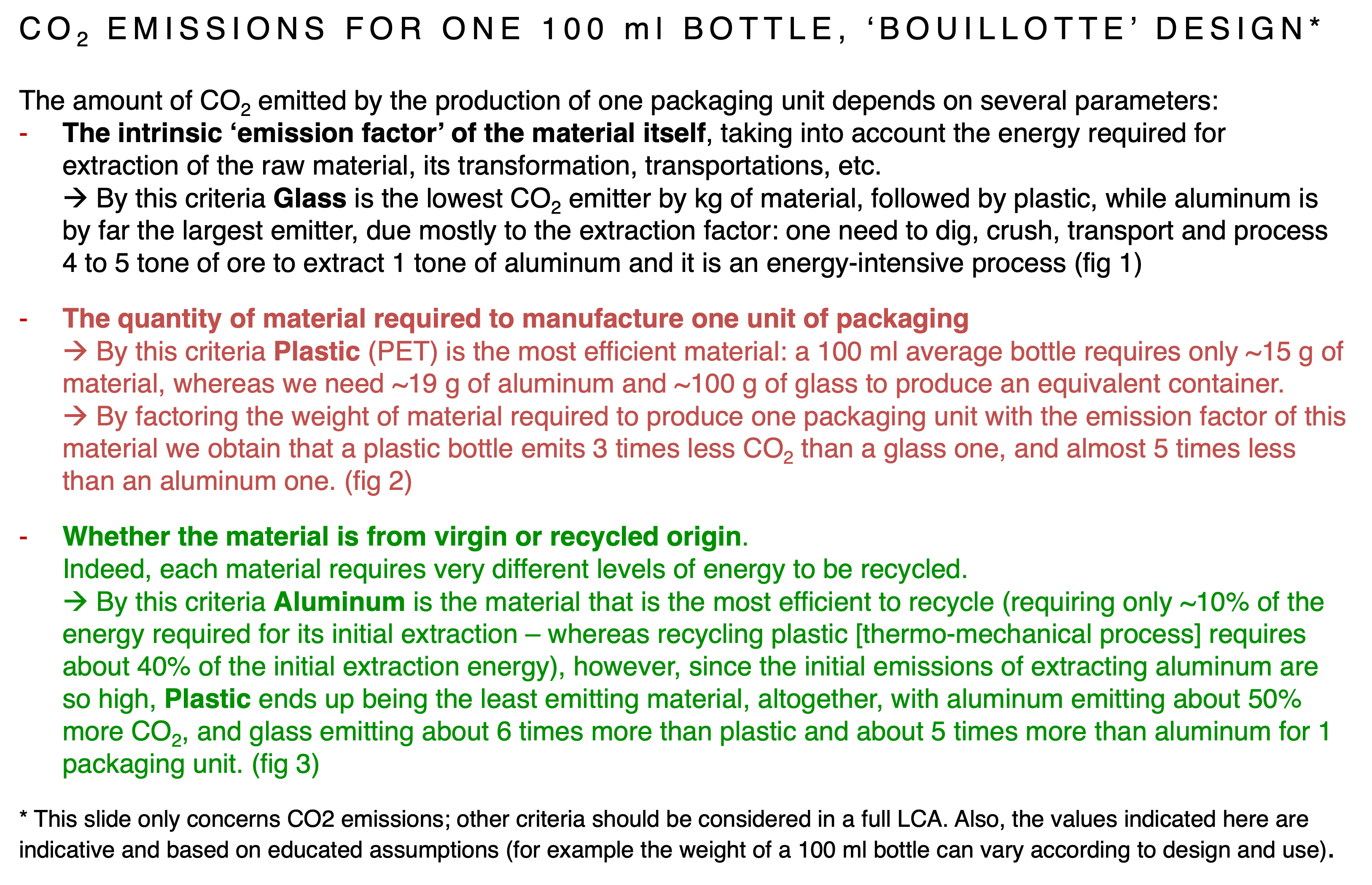

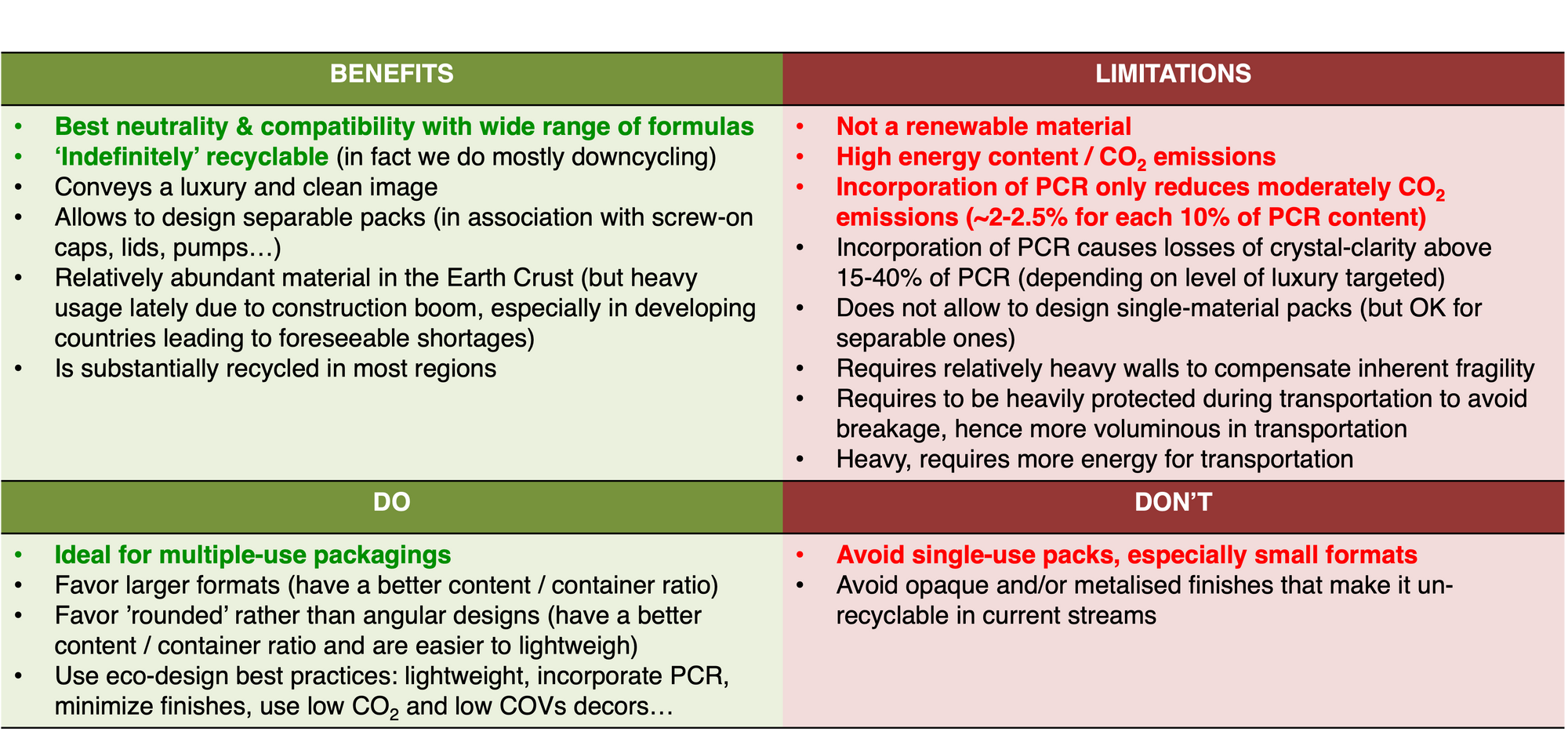

#1 GLASS

Glass is highly regarded as a sustainable material, essentially because it has the reputation of being indefinitely recyclable. This is partly true as in fact what we actually do is downcycling: ultra-flint glass used for luxury perfume bottles for example can accept only a modest percentage of post-consumer recycled (PCR) material (15-40%) before showing a greenish hue. So in reality glass is gradually downcycled into less 'noble' applications, from white glass, to green (wine bottles...), to brown (beer bottles...), and to filling for road surfaces or glass fibers for insulation.

Hence the whole process requires a constant influx of virgin material.

But perhaps the biggest issue about glass is that it requires a lot of energy to be fused, making it a high contributor to greenhouse gas (GHG) emissions and Global warming.

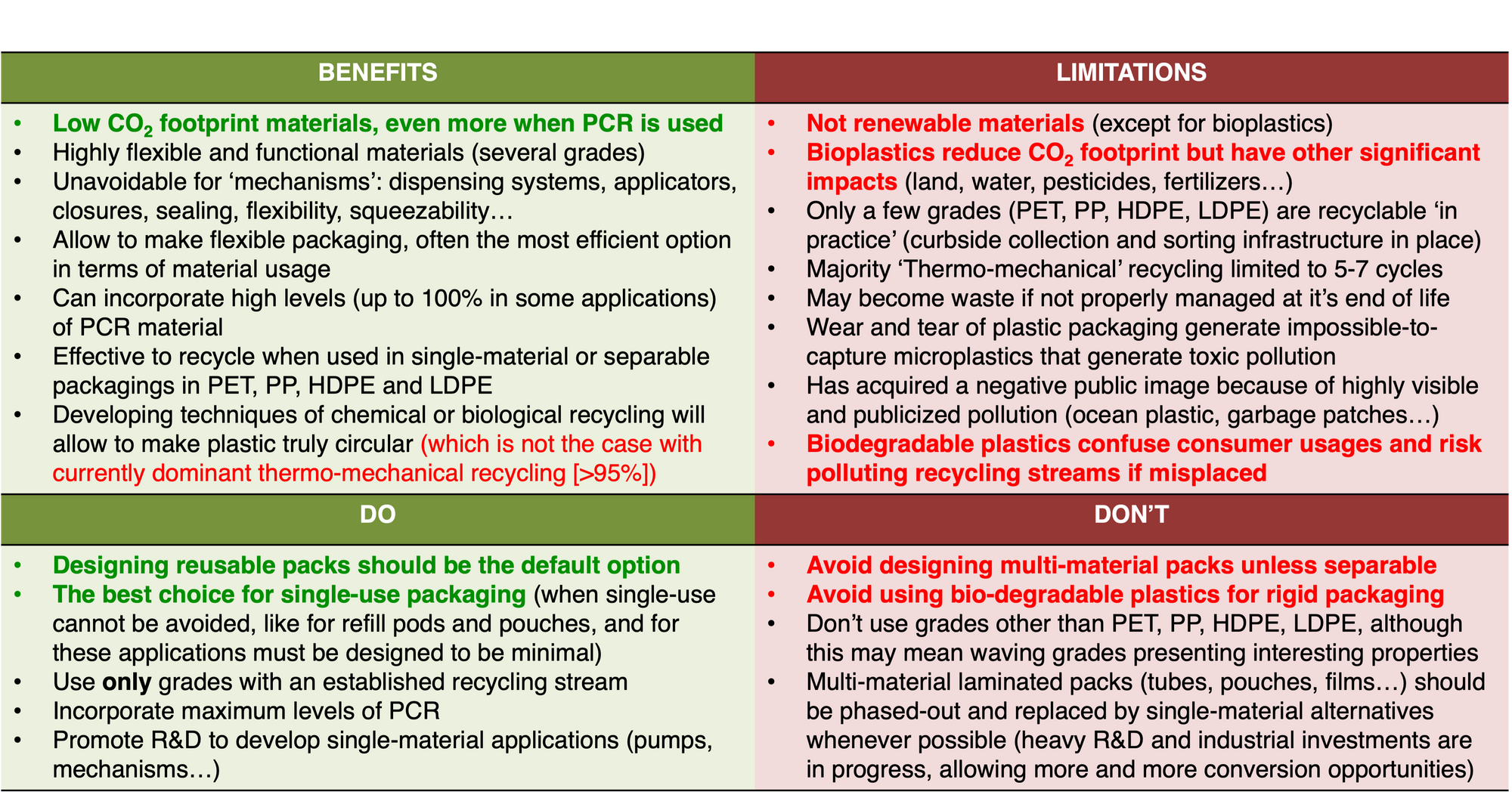

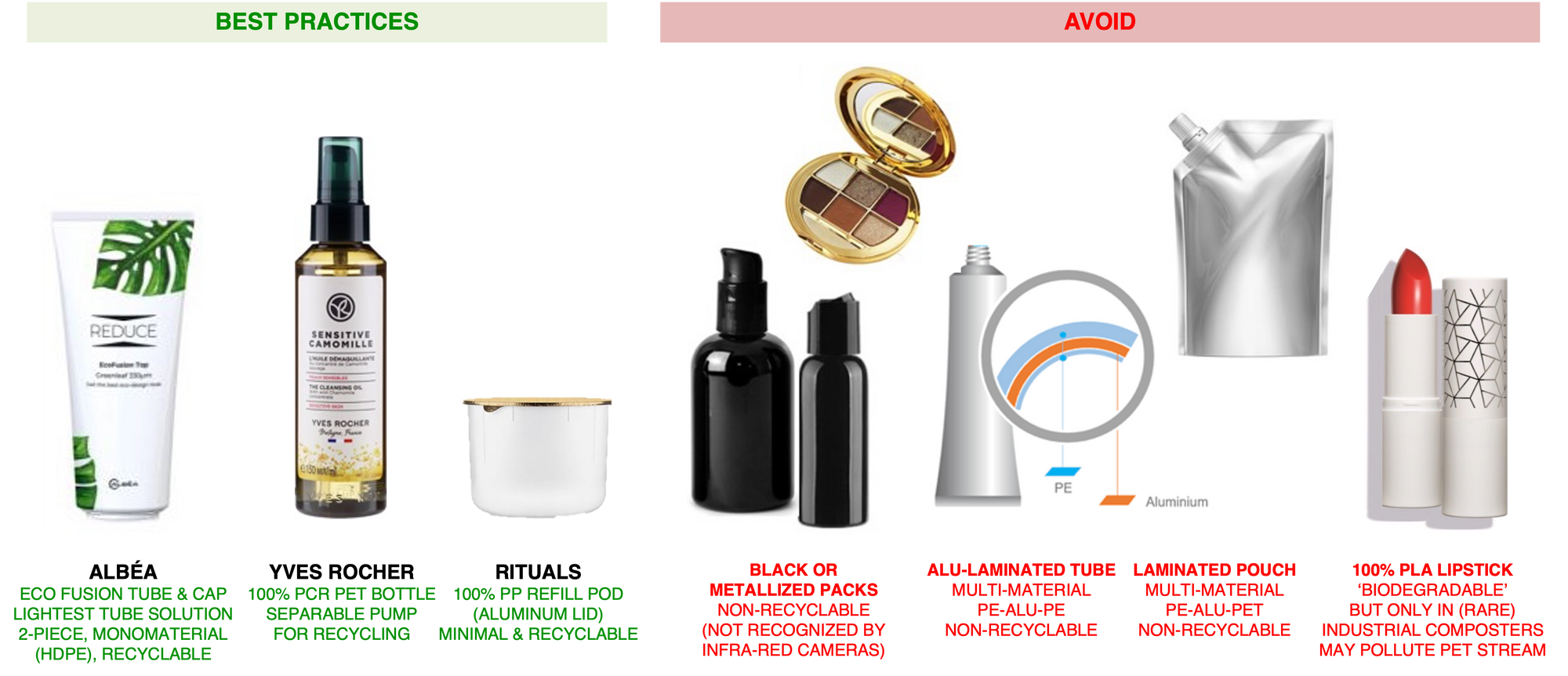

#2 PLASTIC

Plastics suffer from image problems due to unacceptable pollution levels. This is essentially a waste management issue, linked to insufficient infrastructures and cultural awareness in certain regions. Also, collecting, sorting and recycling plastics in a circular fashion is complicated by the huge variety of grades. Practically only a handful of grades are recycled: Polyethylene Terephthalate (PET), mostly used for drink bottles and personal care packaging; Polyethylene (HDPE and LDPE), mostly used for food packaging; and Polypropylene (PP), also used for food, beverage, household and personal care packaging.

Regulations will increasingly limit the use of plastics to the ones beneficiating from established recycling streams, that is the four grades mentioned above: PET, HDPE, LDPE and PP. So plastic packaging should only use these grades.

Plastics are mandatory in a number of functional applications requiring 'mechanisms', like spray pumps, dispensing systems, service caps, droppers, lipstick mechanisms, cosmetic applicators, etc.

But, perhaps paradoxically, plastic packaging is often the lowest CO2 footprint option, because their transformation requires temperatures much lower than glass or aluminum (see below the synthesis section).

Today most plastics are derived from oil, but a growing fraction is coming from renewable bio-materials and recycling

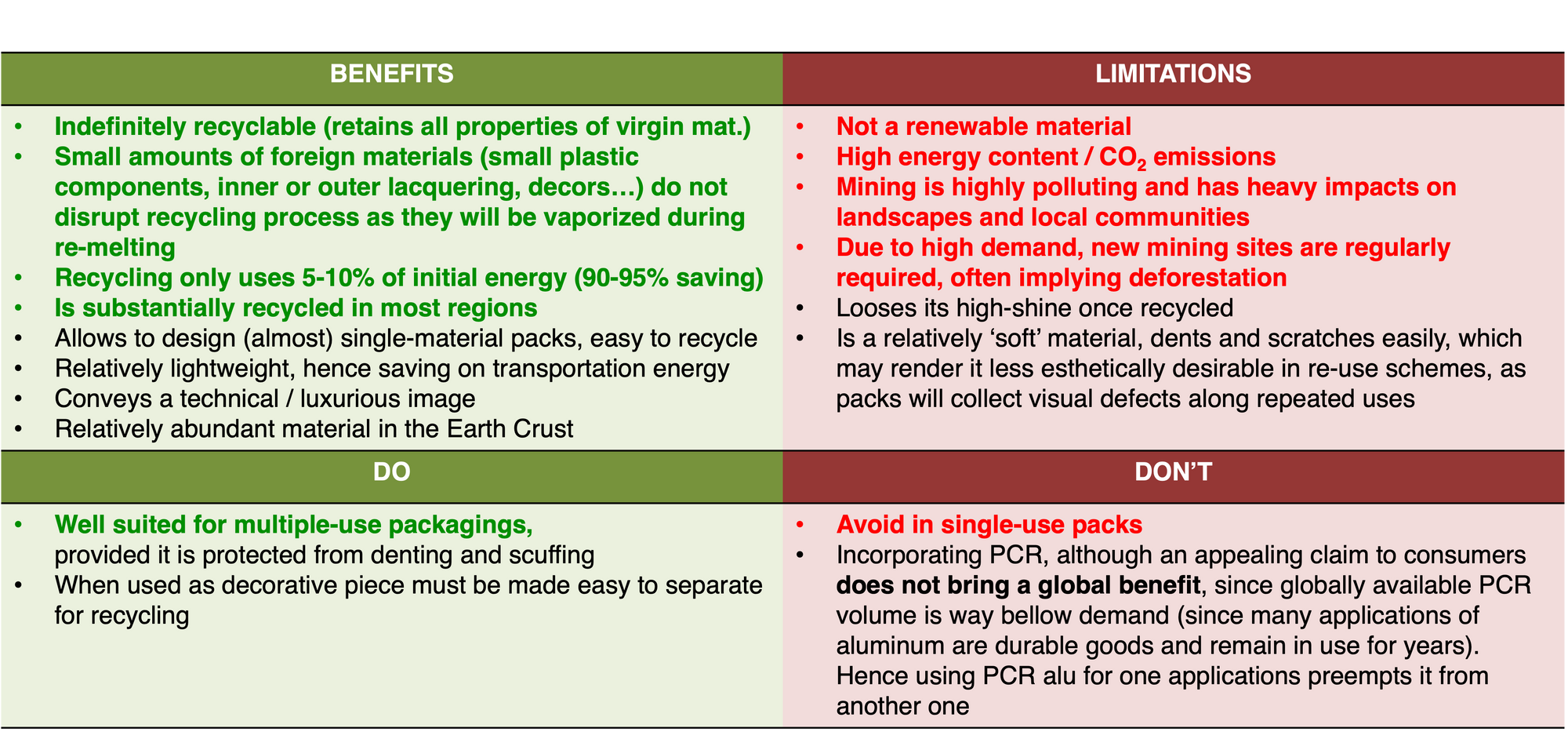

#3 ALUMINUM

Aluminum shares a number of features with glass: it is indefinitely recycled (contrary to glass there is no loss of properties when recycling) but has a high energy / CO2 footprint.

Aluminum is the most recycled material because of its high value but, despite that benefit, demand for virgin aluminum is growing exponentially since aluminum is often 'stored' in durable applications like building. And mining for aluminum is highly polluting and often involves deforestation.

#4 PAPER

Of all materials listed in this article Paper is the only one (with biopolymers) that is renewable. A growing number of logging operations are being certified for sustainable practices.

The biggest limitation of paper is its lack of intrinsic barrier property, making it unsuitable for containing liquids or fragile, perishable products. Hence 'paper' packaging is most of the time a hybrid application where paper is combined with other materials, mostly plastics or aluminum, to provide the barrier to liquids and gasses. This means that most 'paper' packagings are in fact multi-material combinations, which complicated recycling and end-of life management.

A somewhat misleading notion is that, to be deemed 'recyclable' the recycling stream must be able to retrieve (re-pulp) more than 50% of the fibres contained in the initial pack. This is how beverage bricks, which are mostly made of a laminated sandwich of paperboard, polymer and aluminum layers, can be labelled 'recyclable' when in fact only the fibre portion is actually recycled; the residue, a mix of plastics and aluminum (called PolyAl) generally ends up as waste (although some marginal initiatives are trying to find a use for it, like for urban furniture)

Major paper actors are currently investing heavy R&D resources to enhance paper functional properties and its a rapidly evolving field.

Most notable is the fact that paper recycling is not without environmental impacts due to high water consumption (more and more organised in a close-circuit fashion) and the use of de-inking and bleaching chemicals.

#5 BALASTS AND MAGNETS

Ballasts are often used in Beauty packaging to convey a luxurious feel; traditional luxury is associated with heavy materials, so adding weight to, for example, a plastic closure, gives it more substance. This practice however is detrimental to the end-of-life management of the packaging: indeed a plastic or aluminum closure with a metal ballast is a multi-material item that will not fit in any recycling stream and will end up as waste.

Besides, Luxury is a cultural, subjective notion that is evolving, and new generations are challenging the traditional paradigm.

The case of magnets is also an issue: indeed a magnetic closure provides a highly qualitative feeling, but magnets require 'rare earth' metals, like neodymium, which come in limited supply, are highly polluting to extract and are strategic materials for the energy transition: every electrical vehicle (EV) engine and windmill requires neodymium. So its use in 'frivolous' applications raises ethical concerns.

Synthesis

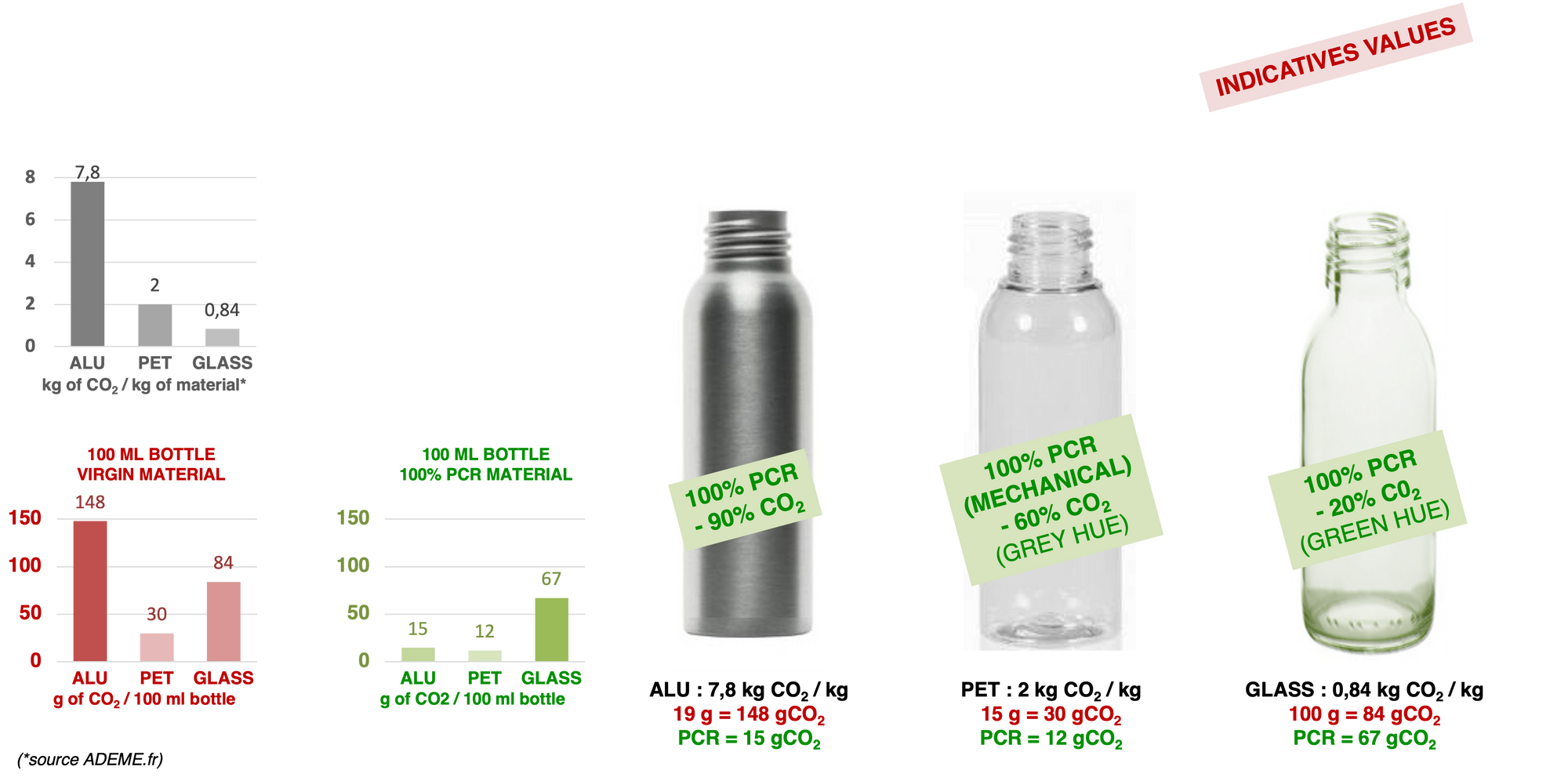

Emission factors of different materials

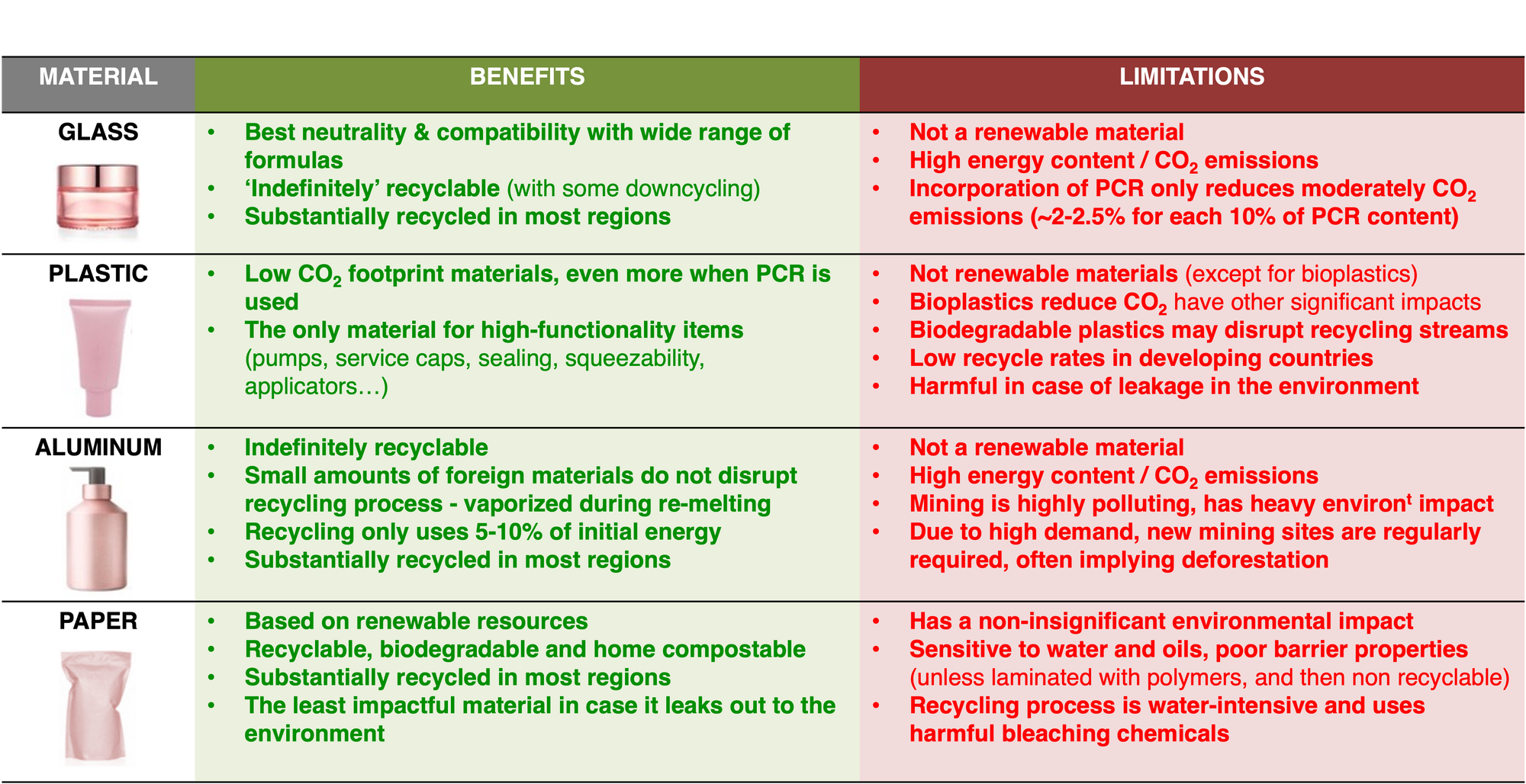

The picture below summarises the CO2 emissions of a typical packaging unit, a 100 ml bottle, made in glass, aluminum and plastic (PET), for both virgin material or 100% PCR.

These are indicative values based on reasonable assumptions. Changes in design or material weight could change these values. (the values indicated represent bottles of minimal weight for the application but the same plastic or glass bottle could for example made heavier with thicker walls). Also, these values are representative of the packaging unit delivered at the filler's plant. They do not represent the total carbon footprint of a real product over its entire lifecycle - which would require a full, case-by-case Life-Cycle Assessment (LCA).