Waterless formulation

While indeed efforts are regularly made to reduce carbon footprint and curb plastic pollution, we should not disregard water, present in more than 80% of most formulas, and which is not an unlimited resource.

---— sign-up and select the FREE option to access this content ------

While indeed efforts are regularly made to reduce carbon footprint and curb plastic pollution, we should not disregard water, present in more than 80% of most formulas, and which is not an unlimited resource. Reducing the water content in products allows reducing their weight and making their transport less polluting. But what are waterless formulation challenges and opportunities?

A wide range of textures

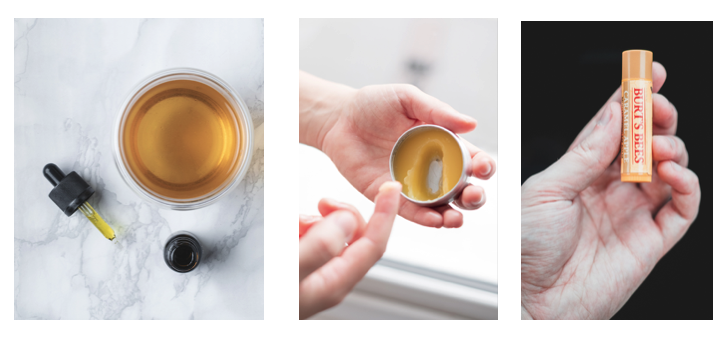

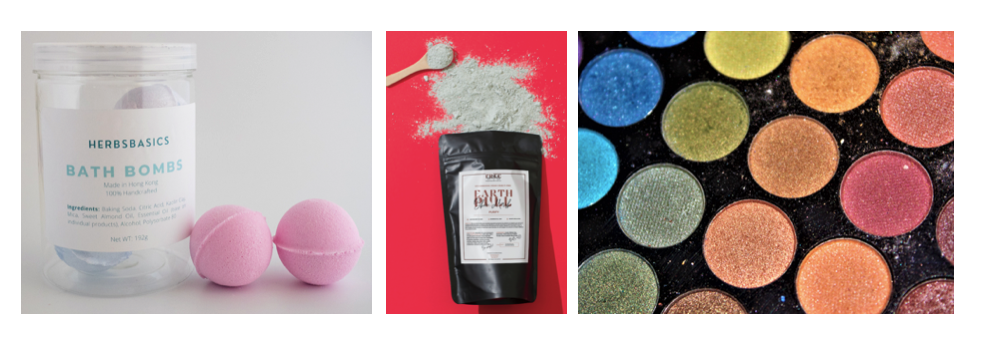

Waterless means water reduction to water suppression (anhydrous), which allows a lot of various textures. If we consider anhydrous products, we can indeed observe different physical forms from liquid to solid, depending on the product's consistency: oils, anhydrous gelled textures, hot poured products in bars, jars or sticks.

Sticks can also be aqueous, anhydrous or emulsion based to reach several sensorialities. And powders can be loose, pressed or granulated. All these galenics belong to waterless products because they only contain little to no water, and offer a lot of sensorial experiences.

Environmental opportunities

Concentrated formulas : waterless formulas contain a little or no water. They are more concentrated, lighter and easier to carry, which has a positive impact on the carbon footprint. At the same time, the waterless versions, if they are in a solid form, are more robust and it’s easier to imagine new packaging solutions, to reduce waste.

Water preservation: the first step consists of reducing water content in cosmetic formulas. But we also have to think of the use of water during all the product development process (raw materals sourcing, product development, industrial process, end-use by the consumer). A good way to know precisely which step requires the most water, is to use a life cycle analysis method. We then get information about each step’s influence on the environment (water save, energy used , waste…).

Formulas to rehydrate : a good option. They are, most of the time, in a solid form, when the consumers buy them.We just have to add some water in a bottle containing tabs or loose powder, in order to rehydrate them and to obtain a liquid product. The advantages are :