Towards a more sustainable glass journey - a case study with Verescence

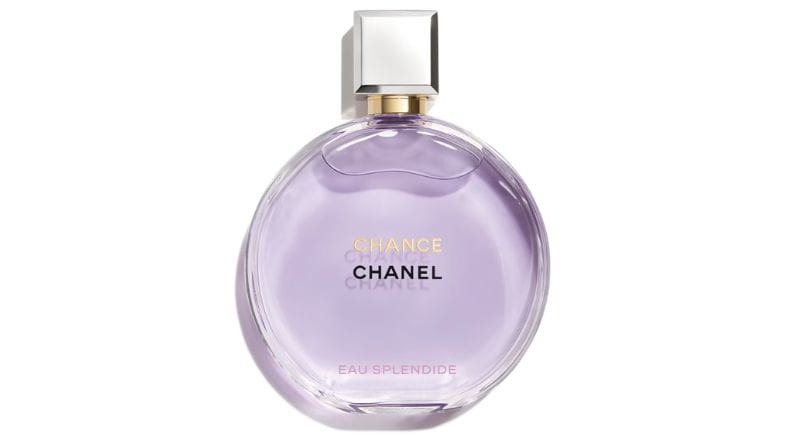

When making luxury glass for perfume, many factors are to be taken into account. From sourcing to raw materials transformation, as well as glass making and bottle shaping, a lot of energy and resources are utilised. How to ensure that the value chain is optimised? How to ensure the best practices are always in place.

We’ve met with Bérangère Raguenet, Marketing and Communication Director at Verescence - the global leader in glass packaging for perfumery and cosmetics - to understand the process of glass making to draw a more sustainable picture for our fragrance and beauty industry.

The global perfumery glass bottle market size was $1,556.2 million in 2019 & is projected to reach $2227.44 million by 2032, at an annual growth of 5.25% (CAGR) in the forecast period, according to Fortune Business Insights. The market is expected to expand with the growing interest from the Asian markets including China and India. Making glass more sustainable is not just a trend but a market requirement to ensure a smooth transition towards a less impactful industry.

re/sources: You’ve created a tool to help your clients make informed decisions about sustainability and the impact of glass packaging on the environment.

Berangère Raguenet: Luckily glass can be fully recycled after use. In essence, it is already a sustainable material.

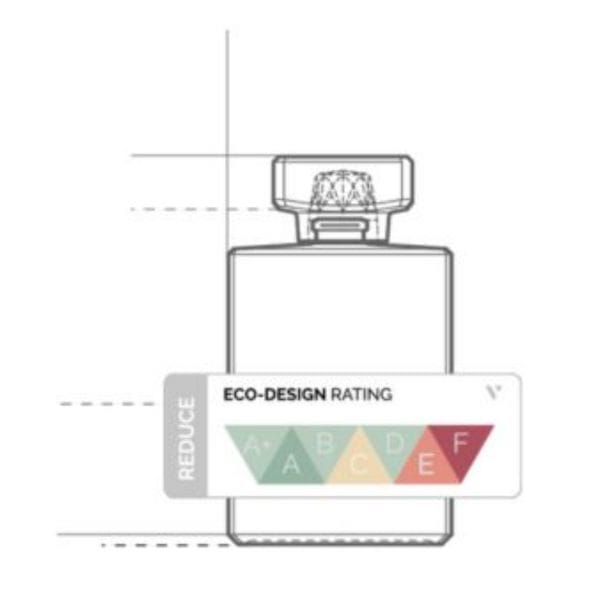

Verescence has developed a Glass Score that allows a clear measurement of the impact of glass on different aspects, to ensure an optimum designing of glass bottles.

For example, a glass container of 100 grams that can accommodate 100 ml of products gets a ratio of 1 in beauty. But imagine comparing this to the drink industry where a glass bottle that can contain 1000ml (or 1L) could weigh up to 1000 gr (or 1 KG) the impact would be disastrous.

So Glass Score gives indications on the ratio of glass per usage (skincare, makeup or fragrance capacity) to improve carbon footprint wherever possible. In other words, this technique allows Verescence and its clients to select the ratio that would have the most impact on carbon footprint reduction.

The tool scales glass design from A+ to F. A+ is the least impactful project (lighter glass), and F is the most energy-intensive.

This information is given from the very beginning of the product development process. Working alongside packaging developers from the brief received. Most products on the market average on B and C, and the aim is of course to target an A score wherever possible.

The shape of the design will have the most impact on the carbon impact of glass. A rounded shape will be easier to lightweight than a very angular and complex design, with very square shoulders for instance.

The idea is not to limit creativity but to foster a responsible design from the very initiative stage of the project.

This tool is mostly a companion of creation, to help make informed decisions.

Knowledge is power, and understanding what will impact the finished packaging at a very early stage is critical to an effective and truly sustainable design.

re/sources: Beyond carbon footprint you are also working on improving the entire supply chain? From sourcing raw materials, to glass making, what have you set in practice?

Berangère Raguenet: Verescence is looking at its entire supply chain to ensure environmental impact is reduced at every stage of the glass journey.

For instance water consumption, resource depletion, oxidation and soil acidification is measured in the Life Cycle Assessment conducted on Verescence glass manufacturing.

We believe that the development of short circuits at our sites is key. More than 97% of our purchases are made with local partners, mainly SMEs/VSEs (figures 2023 were assessed by external firm KPMG).

re/sources: Verescence is also incorporating PCR glass into glass making. You were the first glass maker in our industry to use a high percentage of PCR in the making of glass packaging.

Bérangère Raguenet: Verescence wants to change industry practices and has chosen to systematically integrate 20% to 40% of recycled glass from post-consumer recycling (PCR) in its furnaces worldwide with no impact on the aesthetic quality of our glass. This makes it possible to meet consumer expectations in terms of sustainability, to meet the eco-design objectives of brands, and finally to reduce our energy consumption and greenhouse gas emissions (10% PCR = 5% reduction in emissions) while limiting the use of natural raw materials (sand is replaced by PCR cullet).

Verescence is also able to ensure the recyclability of its products by measuring the transmittance level of coloured or lacquered bottles using an optical laser in order to ensure the safe capture of glass at recycling centres.

re/sources: you are also moving to an electric furnace? When will this technology be operational?

Bérangère Raguenet: Our melting furnaces account for 22% of our CO2 emissions in 2023 (scopes 1 and 2). In line with our decarbonization roadmap approved by SBTi[1], Verescence will progressively electrify these furnaces, which have a lifespan of about 10 years. We’ll start in 2026 with the next rebuilding of our largest furnace at the Mers-les-Bains plant in France. This is a key step towards achieving our goal of reducing our CO2 emissions by 40% by 2034.

references:

[1] In January 2020, Verescence was among the first companies in the glass packaging sector to commit to setting a greenhouse gas (GHG) emissions reduction target by 2022 aligned with the trajectory of the well-below 2° Celsius scenario proposed by the Science Based Targets initiative (SBTi).

[2] As part of its decarbonization plan, Verescence is committed to reducing its CO2 emissions by 40% between 2019 and 2034. Note that between 2016 and 2019 Verescence had reduced its CO2 emissions scopes 1+2 by 19%.

re/sources: Verescence is also certified by Ecovadis and CDP? What scoring have you got?

Bérangère Raguenet: Verescence has been awarded the Platinum EcoVadis medal for its social and environmental performance (CSR). This is the fourth consecutive year the company has received this ranking. The Platinum medal is the highest level of recognition given by EcoVadis, the world's most trusted provider of business sustainability ratings.

All of Verescence European and American plants have also maintained their platinum medals, with each scoring over 80%, placing them in the top 1% of the 130,000+ companies rated worldwide. Additionally, Verescence's South Korean site has improved its score by 2 points in its second evaluation, now ranking in the top 15%.

Verescence is also among nearly 400 companies out of the 21,000 globally assessed by CDP recognized for their leadership in environmental transparency and performance on climate change (A-) and water security (A).

.png)