The best of Luxe Pack Monaco 2025: From monomaterial innovations to upcycled typhoon sludge

Returning to the Côte d’Azur from 29 September to 1 October, Luxe Pack Monaco’s 2025 edition teemed with premium packs befitting the annual expo’s glamorous location. Whether new concepts, or a demonstration of exhibitors’ savoir faire via this year’s standout beauty launches, the packaging on display was frequently sustainable and/or ergonomic – and inevitably gorgeous.

re/sources was on site to discover standout innovations and exhibitors – which you can discover below. You can also watch our live videos, demonstrating the innovations, on our Instagram.

Creative upcycling

Pre- or post-consumer recycled content options for materials with mature recycling streams, such as aluminium and polypropylene (PP), are, by something of an expected baseline, but some exhibitors demonstrated that almost anything can enjoy a second life as packaging.

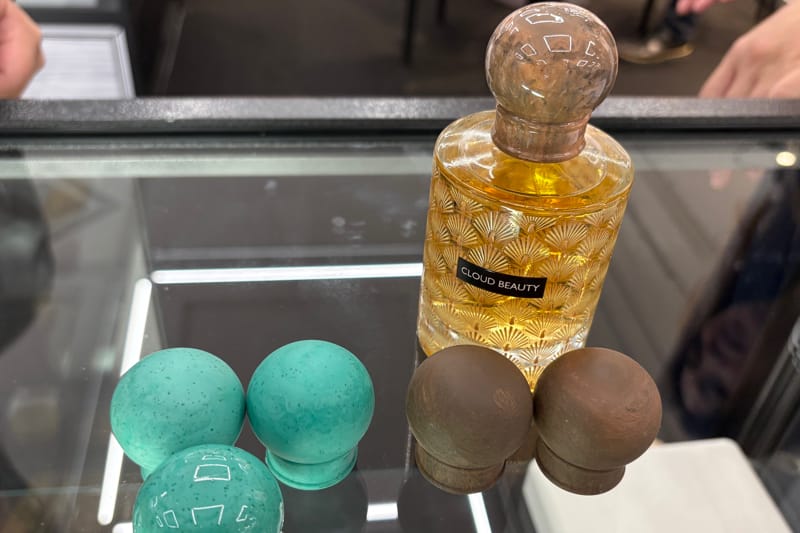

Extreme summer weather in Taiwan results in excess mud and sand being washed into reservoirs, requiring cleaning. This clay-like substance has been upcycled into pellets for industrial processing and developed by Luxe Pack Monaco exhibitor Cloud Beauty into a low-carbon, food-contact safe packaging material called Sludge. The aim is to valorise an abundant waste resource while reducing conventional plastics content in caps; example caps from Cloud Beauty combine PP with at least 70% Sludge. In addition, the soft-touch, clay-like substance’s high density eliminates the need for added weights in caps.

A new concept from Devi, meanwhile, makes use of unsold roses, lavenders and forget-me-nots from China’s Yunnan province. This agricultural waste is combined with biodegradable, naturally-sticky Pu’er tea adhesive for caps that decompose within five to six months under composting conditions. While the technology is limited to square and rectangular shapes, caps boast the benefit of being self-scented, retaining at least 88% of their natural fragrance for up to 60 days.

Another creative use of floral waste was the gua sha style massage accessory for Chanel by Faiveley Tech, which scooped a Formes De Luxe award. The applicator is made with upcycled camellia seed shells, a signature active ingredient in the designer brand’s N° 1 skin care line. The camellia byproduct is encapsulated in the centre, while the outer layer is made from the biosourced material Sulapac, which has the soft, sensory qualities desired in a cosmetic applicator.

Textiles industries likewise served as sources for materials continuing their journey as luxury packaging. There was a huge crowd at the booth for German mill Gmund, which debuted Gmund Manteco at the show. The new premium paper collection is made 100% from leftover cotton fibres from Italy. Created in partnership with luxury textiles supplier Manteco, papers in the collection are made from two types of cotton industry waste: 50% short seed fibres called linters, plus 50% fibre waste produced during the cotton cleaning and spinning process. Gmund Manteco comes in 320gsm thickness and is available in seven colour options.

Suitable for washbags and accessories, Pélinova is created by hydrojetting pre-consumer recycled leather fibres onto TENCEL lyocell to make a supple, durable material comprising 50% recycled leather. The recycled leather material’s production uses 70% less water than traditional methods, which bond leather fibres with rubber, while also reducing CO2 emissions.

Woola, meanwhile, went straight to the four-legged baa-ing source for its waste repurposing material. The Estonian exhibitor offers protective packaging made from wool that would otherwise go to waste. It buys unsellable wool from small farmers in Estonia, before washing and felting the wool into an elastic, water-repellant and extreme temperature-resistant alternative to bubble wrap. Suitable for concepts including mailers, bottle sleeves and protective wrapping sheets, Woola says its reusable material makes for a unique unboxing experience.

Ergonomic sustainability

The European Union (EU’s) Packaging and Packaging Waste Regulation 2025/40 (PPWR) entered into force on 11 February this year. One of its core aims is to make all packaging on the EU market recyclable by 2030, which means there’s been even more pressure on packaging firms to develop recyclable, monomaterial solutions that operate to the high standards consumers expect from traditional systems.

Take the pump-on-tube packs beloved by the likes of L’Oréal’s CeraVe. Luxe Pack exhibitor Silgan Dispensing recently surveyed Chinese, European and US-based beauty consumers, discovering that 61% felt a pump-on-tube elevated their user experience (compared with 25% for a flip-top cap and just 15% for a screw-on). Additionally, 40% said they would keep buying pump-on-tube products over a screw cap version even if the latter were lower priced. The research coincided with the launch of Silgan’s ERA, its five-years-in-the-making all-plastic engine. Combined with a polyethylene (PE) tube in 35mm or 40mm, and compatible with Silgan’s Soprano and Modern head styles, plus M17-32 Emotion or M17-32 Sensation closures (in matte or glossy), the use of ERA makes for a fully recyclable airless pump-on-tube solution. It is compatible with a wide range of formulas, including skin care, sun care, make-up, and hair care, and delivers 95% product evacuation. Because beauty consumers are uncompromising when it comes to user experience, ERA has been engineered to offer both ultra-soft and controllable dispensing.

Another new monomaterial plastic pack is Albéa’s Endless Kiss lipstick from the supplier’s Designed For Recycling make-up concept. The all-PP lipstick is made up of just three parts, but without any compromise on the smoothness of the mechanism, according to Albéa. Part of the same concept, its Hype PET compact is a 100% polyethylene terephthalate (PET) with a metal-free hinge, available in 100% or 30% PCR versions and refillable.

Many Luxe Pack Monaco innovations reflected the dermatological skincare trend with packs constructed to protect precious, active formulas and ensure correct dosage. Aptar introduced the Derma Series, which draws on the company’s pharma history for a series of different packs that meet dermocosmetic specifications, as well as its Astrea Airless. This high-performance piston airless dispenser is matched with transparent tubular glass bottles, in sizes 15ml, 30ml or 50ml that are type 3 recyclable in the glass stream. The Astrea Airless is said to have excellent compatibility and high-speed filling, making the airless option ideal for dermocosmetic brands.

Albéa compact, The Guardian, meanwhile, provides airtightness achieved both via liner compression and screwing the cover with a multipoint locking system. Developed for premium formulas, suncare, foundations, or formulations with volatiles where the brand wants to provide extra protection, The Guardian has a novel opening mechanism, whereby the user twists it one quarter like a jar, before opening it like a normal compact. This has been developed for premium formulas, suncare, foundations, or formulations with volatiles where the brand wants to provide extra protection.

Cosmogen expanded its plastic surgery-inspired Needle Tubes range (which feature ultra-thin aluminium applicators) with aluminium laminate tube versions, offering enhanced formula production. According to Cosmogen, its Needle Tube ABL is suited to products with concentrated or fresh ingredients, or those containing oxygen- or sunlight-sensitive ingredients. The tubes may be paired with aluminium caps, for fresh touch and visual enhancement.

Precision dosing

The further expansion of Cosmogen’s tubes line-up to include Expert Needle Tube (a pipette-shaped twist on Needle Tube for precise area treatment) and Dropper Tube Alu (developed for facial treatments) answers the dual needs for application control and medically-coded aesthetics in skincare, makeup and hair care.

Axilone likewise developed a Beauty Pen concept in response to its clients’ hybrid formulas that combine care and colour. Making use of the company’s lipstick manufacturing expertise in both plastic and metal, the customisable pens come in two versions, push button and rotating, and are compatible with both solid and liquid formulas. The pens are refillable, with a single-material cartridge allowing for recyclability, and multiple applicator options to adapt to the formula and dispense the right dose.

Designed for use with trending creamy and balm-like lipstick formulas – which have an increased risk of breakage if too much of the bullet is exposed – Albéa introduced Love Beat. When turned, Love Beat’s mechanism provides a discernible click, indicating to the user that they have the correct dosage.

Finally, Nuon Medical brought its signature therapies to new applicator types. Among its launches for 2025 was Derma Roller with Phototherapy Activation, which introduces a microneedling effect (thanks to 2mm needles affixed to removable self-adhesive strips) to aid formula penetration, combined with collagen-renewing red light.

Greener finishing touches

From more sustainable decoration, to labelling and traceability which doesn’t compromise on ethics, Luxe Pack Monaco exhibitors proposed finishing touches for maximum visual oomph with minimal environmental impact.

Kurt has released a new decoration sheet that just applies on cold transfer. No more hot stamping and heat, meaning the plastic subtract doesn’t sit on the packaging anymore as the PET layer remains intact. Only the ink is deposited on transfer, and represents 1.5 to 3 micrometers, with just 0.00002mm of aluminium (6000 times thinner than human hair) . The used PET sheet can then be collected and sent back to Kurz for recycling in their next manufacturing. The collection only happens at the next product delivery to avoid unnecessary back and forth travel. As for the used film Kurz can collect up to 99% of the product, in mechanical recycling, remaking into rPET films. Before this operation, used films were just burnt.

Altus Coating offers a water-based UV curing technique as an alternative to traditional UV-curing varnishes, with a maximum VOC content of 10%. The technology is said to be less toxic to humans, consumes less energy and uses fewer petroleum resources.

Scooping a Luxe Pack in Green Award in the Eco-designed Packaging Innovation category this year was Belgian company Ma Balise with its green upgrade on RFID and NFC labels. Standard NFC tags comprise seven layers, including a chemically etched antennae, a PET adhesive layer and a silicone one. The options offered by the first-time Luxe Pack exhibitor (including combination NFC and RFID tags) are made from just four: FSC paper, a metallic ink-printed antennae, and a wet layer made up of an adhesive and release liner. The biodegradable tags (biodegradable in 30 days and compostable with organic waste) are said to be ideal for eco-conscious brands looking to meet upcoming European Digital Product Passport rules without compromising on their ethos. Suitable for traceability, storytelling, authentication and connected services, these flexible labels can be integrated into luxury packaging, including rigid boxes or hangtags.