Phenix en provence upcycles tomato waste for cosmetics ingredients and packaging materials

Imagine a lipstick where colour is not just a colorant but has also skincare benefits? While super sustainable this is super effective. Marrying the market need for greener alternatives with optimum potency. We call it smart biotechnology!

Who said sustainability was boring. Not us!

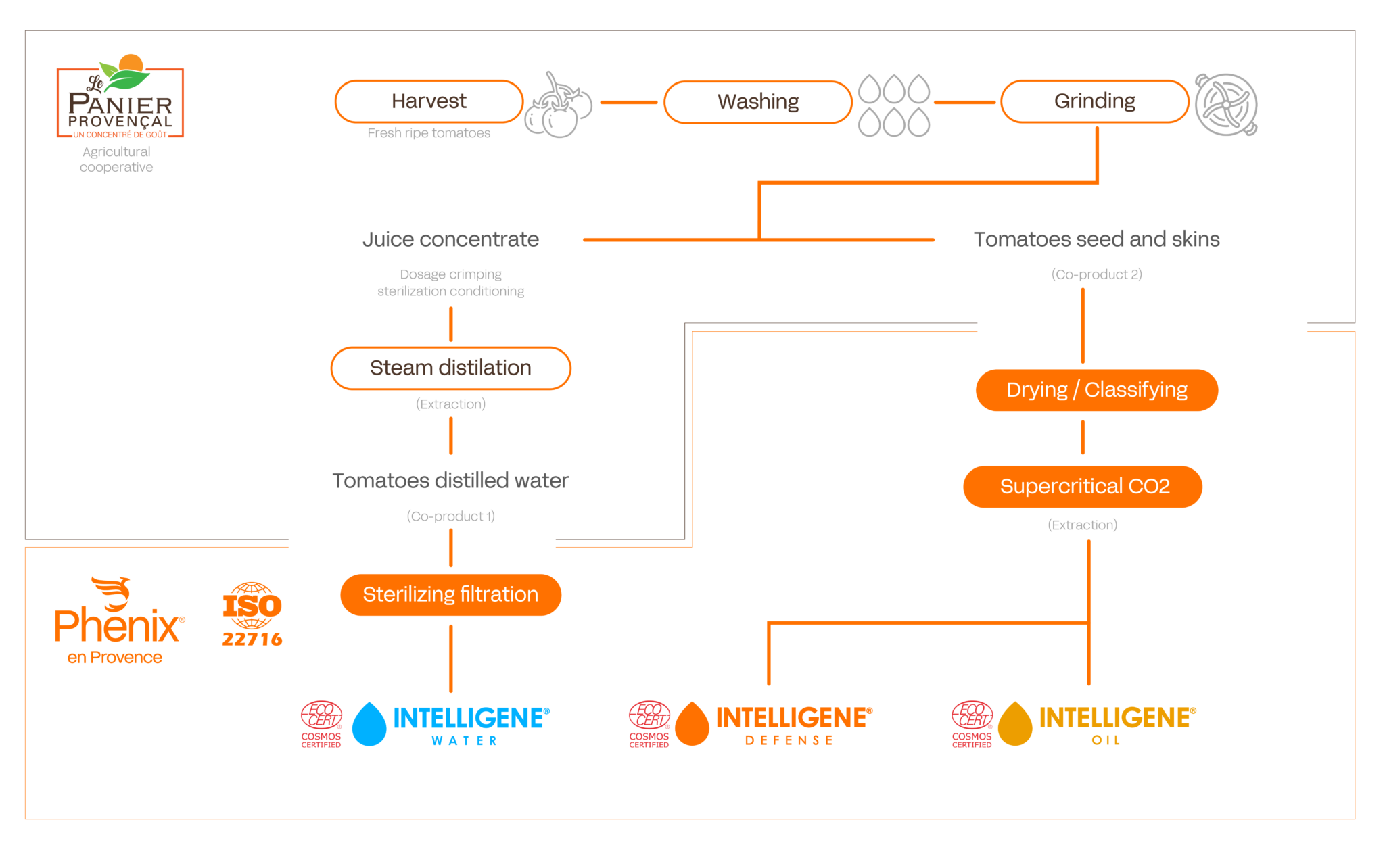

The beauty start-up Phenix en provence, based in the south of France (if you know your geography you may have guessed it in the name ;-)), has developed a sustainable sourcing strategy for the tomato waste and after years of R&D has developed active and functional ingredients as well as source materials for packaging.

On the Ingredients side

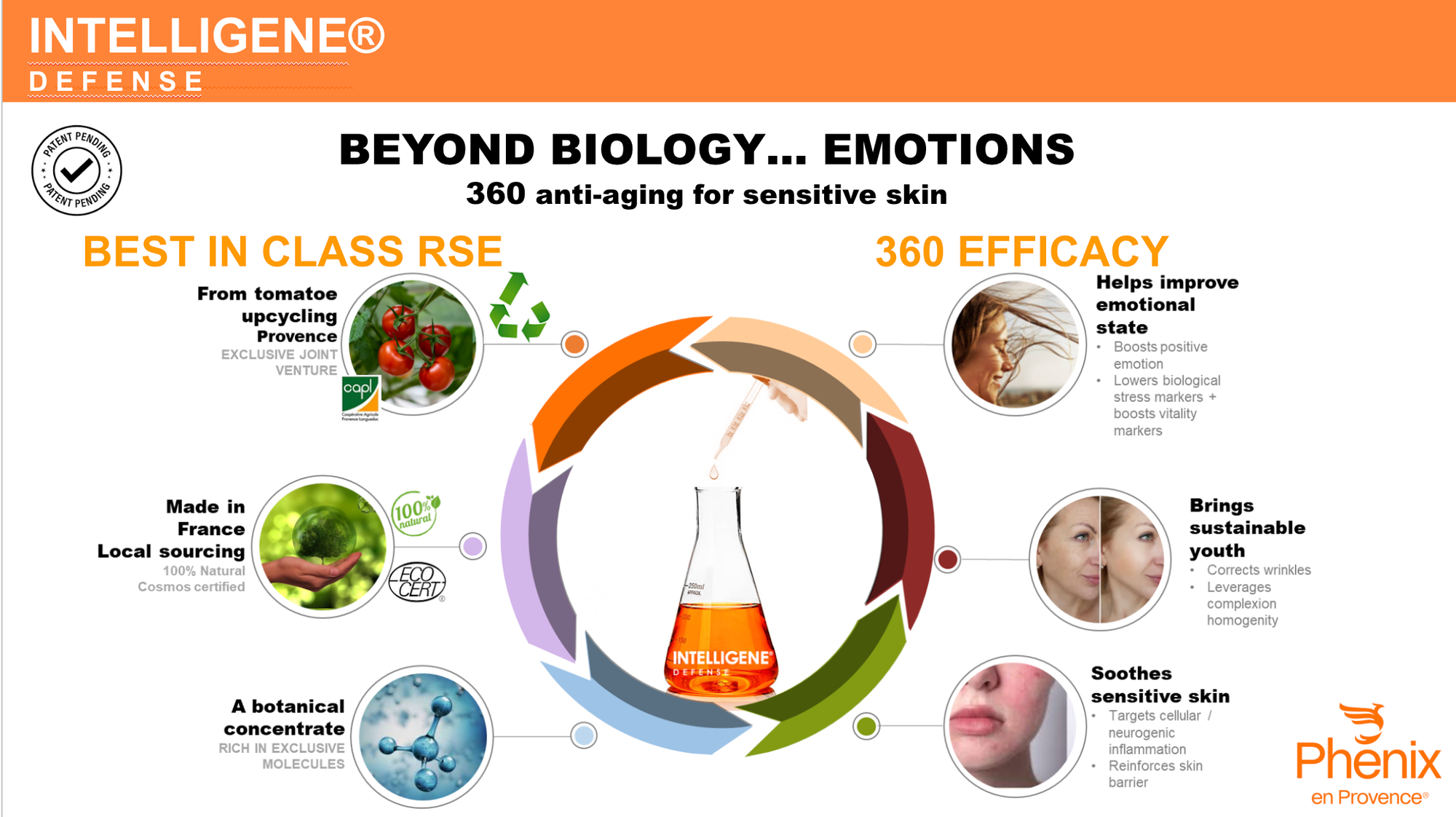

Phenix en provence® is a 50-50 joint venture, born from the partnership between the Agricultural Cooperative of Provence Languedoc (CAPL) and the independent R&D firm INATURALS, creators of natural ingredients. They develop natural and innovative cosmetic ingredients, concentrated in amyrins, obtained by upcycling and adding value to tomato co-products from Provence. It is effective at repairing the skin while providing immediate hydration and soothing. The results of the clinical study demonstrate that from the very first application, subjects with sensitive skin found their skin soothed, moisturized and supple.

Some of the examples of the formula developed with these ingredients include make-up and skincare applications: with a lipgloss, a blush and a micellar water.

- A lip gloss formula with Intelligene® Defense that has “Clinically proven efficacy for: Soothing, Moisturizing, Skin barrier restoration and reinforcement, Anti-aging, Wellbeing improvement. “

- Blush formula: “ Destined for very fragile, extra-dry, itchy, reactive, and mostly skins with redness. The smooth and beautiful color of this blush formula will protect your sensitive skin from discomfort sensations using organic Intelligene® Oil. Thanks to its emollient and moisturizing properties, you will be able in a single step, to gently apply makeup and take care of your skin, during your daily makeup routine.”

- Cleansing Water: “micellar and anti-aging water for everyday use without rinsing. Formulated to gently remove excess of sebum and maker-up while soothing and protecting the skin DNA from UV-rays, thanks to INTELLIGENE® Water technologie. Content 85% of INTELLIGENE® Water, a tomato fruit water from organic farms located in Provence Region, which naturally provides natural minerals from tomatoes, including calcium and zinc, which nourish, hydrate, soothe and protect the skin from UVA-UVB damages. Ideal for sensitive skin, before or after sun exposure. Without ALCOHOL. Biological effects of INTELLIGENE® Water: Photoprotection (on NHEK models stressed by UVA+UVB rays). “

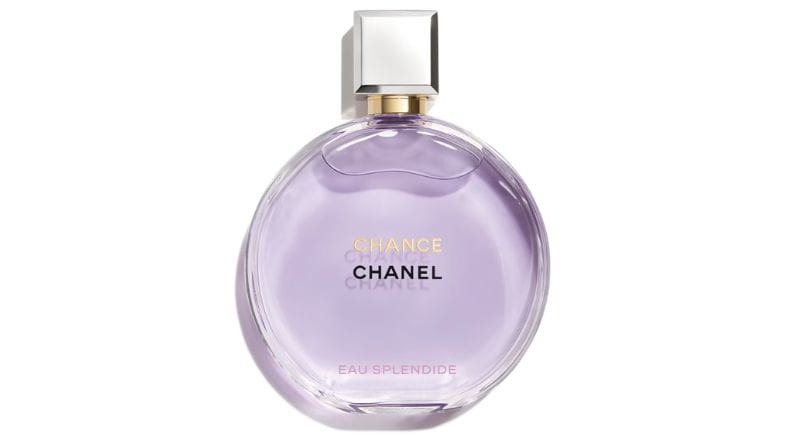

The start-up has signed a partnership with Robertet, a notable fragrance company. The partnership is based on the synergy between Robertet's historical excellence in sourcing and creating high-quality natural ingredients, and Phenix en Provence's expertise in turning agricultural by-products into high value-added active ingredients. From an industrial standpoint, Robertet master extraction using eco-responsible processes and an approach based on green chemistry, while Phenix en Provence deploys a state-of-the-art industrial platform to transform agricultural by-products into high-performance natural ingredients.

On the packaging side

As we wrote Phenix en Provence collects waste from tomato production to upcycle it in cosmetic products as ingredients in formulas or raw materials for packaging. For packaging application Tomato seeds, skins and hydrolate are recycled into pellets and mixed with natural resins to produce biodegradable materials such as PLA (PolyLactic Acid).

This is currently an industrial pilot study carried out in a bioplastic matrix (PLA) through the micronisation and compounding of 5 kg of PLA material + 20% tomato peelings micronised to 1 mm. This enables the production of injection-moulded products such as solid packaging such as cream pots or make-up compacts.

This doesn’t come in competition with the food industry as it’s a waste, and would be mix in any other food product.

This industrial example demonstrates how our economy can achieve innovations with a complete life cycle by using waste to feed another organism, as nature would do.

The start-up is under the industrialisation phase and estimates a development and full industrialisation within the next 3 to 5 years.