Luxury packaging didn’t disappoint in Monte Carlo

This week, Monaco was again the annual mecca of luxury packaging. From luxury caps to intuitive designs and articulate accessories, great innovations were to be discovered.

A new marble finish thanks to Sulapac® biobased materials

Released in June 2024, FaiveleyTech has created a cap with a marble effect using the Sulapac® compostable material. For over five years, FaiveleyTech has been experimenting and developing solutions with Sulapac® materials and has gained critical knowledge for luxury applications.

“Perfume closures have been made using Sulapac Luxe Flex, a highly functional bio-based material designed to replace technical fossil plastics in packaging for the beauty sector. Thanks to the transformation process, the marbled pattern is repeatable while respecting the uniqueness of each piece. For brands, this innovation opens up new possibilities for exclusive, elegant and eco-responsible aesthetics,” expressed FaiveleyTech.

The material used for the marble effect is one of the 9 on the panel for luxury homes. The integration of this new effect is part of a global eco-design approach. FaiveleyTech has explained its strategy to develop eco-responsible materials (bio-sourced materials, recycled materials), which require less post-injection treatment and offer great potential for enhancement.

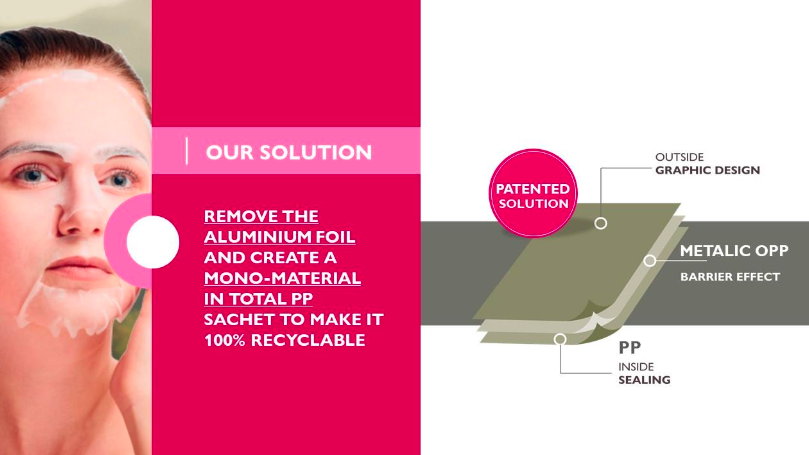

Fully Recyclable Packaging for Sheet Masks

Developed by Lessonia in France, the product design significantly reduces its environmental impact by transitioning from a multi-material to a mono-material structure. Traditional sheet mask sachets consist of three layers: PET, aluminum, and PE, making them non-recyclable by developing an all-OPP (mono-material) sachet. The product is fully recyclable, drastically reducing waste and environmental pollution. Additionally, polypropylene protective liners have been removed, and innovative supports that do not require such protections have been opted for.

Lessonia approach ensures that the new mono-material sachet maintains essential

functionalities such as printing, sealing, and barrier effects without the environmental costs associated with traditional materials.

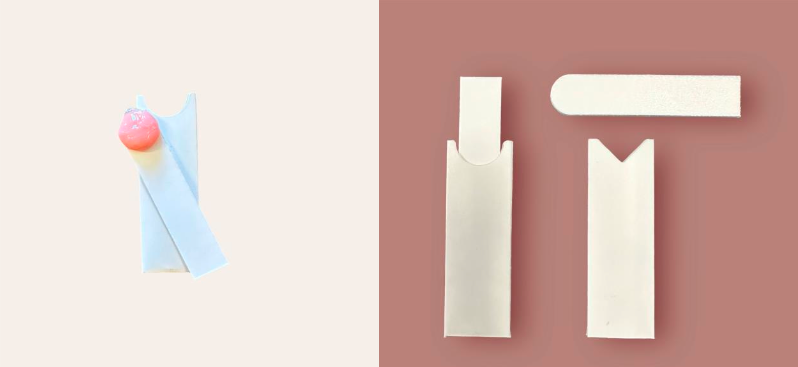

Paper Spatula by Martinenq

Martinenq has developed customised casing cut-out for optimum spatula handling. The design of the spatula ensures the product is even applied. Fully customisable spatula sleeve for brand communication (embossing, hot stamping, etc.). 100% PAPER.

This spatula is made of cardboard to replace current plastic testing spatulas. The packaging is made from a single material using a more eco-responsible approach.

The paper used is: FSC, biodegradable, recyclable, Acid-free, and Chlorine free.

Using 100% disposable paper spatulas limits waste and means that they can be recycled. This product is a solution to current market growth and strong customer requests for local production, which aligns with their CSR approach (recyclability, cost reduction, etc.). Due to its single use, it can be delivered ready to go.

UV Protection for Color and Fragrance Preservation

Developed by Stoelzle with the NexDot technology, Lumi Coat shields products from harmful UV rays without affecting visible light, ensuring glass bottles remain optically clear. This advanced protection prevents colour changes and fragrance degradation, eliminating the need for traditional UV additives like Avobenzone and supporting cleaner, more sustainable formulations.Acid-free

Sustainable and "Clean Beauty" Ready Lumi Coat aligns with the growing demand for "clean beauty" by reducing the need for stabilizing molecules such as UV absorbers, dyes, and preservatives. Eco-friendly and safe, Lumi Coat enhances product sustainability while delivering consistent, precise UV protection.

With a 10.5% improvement in the single score metric for anti-UV perfumery ingredients, Lumi Coat enables the development of perfumes with fewer stabilizers and external additives, supporting brands in creating cleaner formulations.

Flexible Integration with Glass Designs Lumi Coat integrates seamlessly with various glass packaging designs, offering brands flexibility while ensuring the highest level of UV protection.

Home compostable overcap for the protection of luxury packaging

Developed by Sleever International, Seelcap® Onego is a home compostable overlap. This solution ensures the security of packaging (tamper-evidence). It consists of a shrinkable overcap made from a new home-compostable material, featuring a fully integrated opening mode.

This solution reduces the environmental impact of materials with a non-identified recycling stream. This circular solution has been developed thanks to a strategic partnership combining Sleever® mono-oriented film expertise and Carbios® biodegradation expertise.

While improving circularity and it also reduce the carbon footprint of the product, which by its very nature is impossible to recycle because of its reduced size (< than 60mm).

Seelcap® Onego remains a single piece after opening, fully compostable and leaving no trace behind thanks to its unique opening design. This single piece is easy to open and reduces the risk of littering in nature.