How Capardoni is reclaiming packaging made in Italy

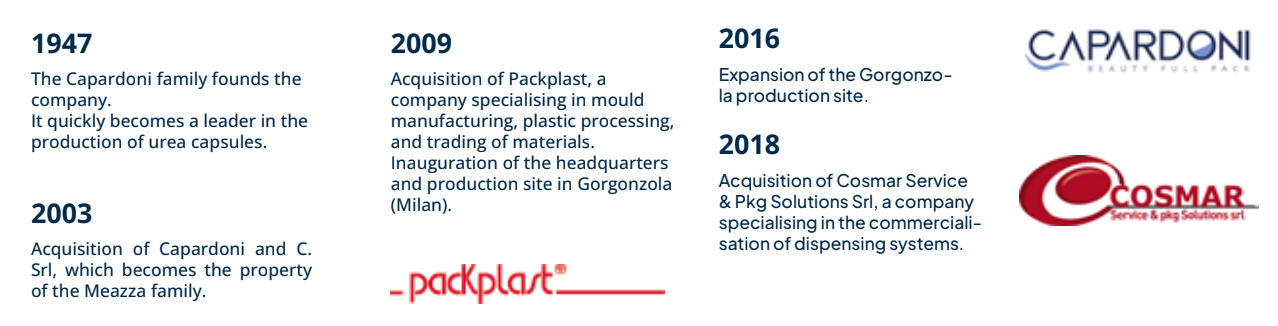

The Capardoni Group, since the Meazza family's acquisition in 2003, has expanded significantly through seven acquisitions, including the recent merger with Capsol in November 2024. This merger increased their combined turnover to over €50 million by the end of 2024 and expanded their workforce to 149 people. The company now offers packaging for the beauty, perfumery, pharmaceutical, and food sectors, with a focus on innovation and sustainability.

Standard and Custom Packaging

The company aims for industrial self-sufficiency, extending to manufacturing their own moulds and energy sources. They offer a wide variety of packaging solutions including standard and exclusive products for skincare (jars, glass/plastic bottles with accessories), nail polish (complete packaging solutions), perfumery (glass bottles with various accessories and custom decorations), home fragrance (glass packaging), and body care (PE, PET, PETG packaging with accessories). They also produce caps for aluminium tubes for the food sector. They also offer eco-friendly options, such as bottles, jars, and caps made from sustainable materials.

Latest Innovations made in Italy

Capardoni has recently developed new products, including the compact Tottle Nevis 30 ml bottle, the mono-material PP dropper, the "Diamond" dropper, the "360° Security" flip-top cap, the Chico glass bottle, and the Ruby Stick. The Italian manufacturer has also developed specific packaging solutions for the Italian apparel brand Intimissimi.

The Tottle Nevis 30ml features an innovative compact design and pocket-sized format, ideal for on-the-go use, particularly suited for liquid and creamy formulas such as foundations, serums, and hair care products. The bottle is made from HDPE or PP, while the cap is made from PP, making it recyclable.

The monomaterial PP dropper is a single-material PP dropper, an eco-friendly solution that retains the same functionality and ease of use as traditional droppers. All components are made of PP, with the collar available in recycled PP (r-PP). There is no need for disassembly at the end of use, making it easier for consumers and ensuring an optimal recycling process. Using PP for the tube instead of glass reduces the risk of breakage during transportation and filling. The tube colour can be solid, transparent, or semi-transparent.

The “Diamond” dropper is a monomaterial dropper that features a designed diamond-shaped nipple. Its unique shape enhances aesthetic appeal but also provides a comfortable and precise grip for effortless dosing. All components are made of PP, facilitating recycling, reducing waste, and promoting sustainability.

The "360° securtiy" flip-top cap is a patented design adapted to e-commerce needs for safe logistics. Once screwed on, the cap cannot be unscrewed, ensuring tamper-proof protection and guaranteeing product integrity. This is a cost-effective and eco-friendly patented cap. The flip-top lid, featuring a tamper-proof seal, fully protects the bottle contents. Thanks to its anti-unscrewing system, there is no need for shrink sleeves to ensure tamper-evidence. Ideal for promotional bottles or online sales. It is available in four versions.

The Ruby Stick is a lightweight, compact, and monomaterial skincare stick. It has a 5g capacity and is uniquely made of PP, suitable for many formulas. Its minimal design and functional structure make it a versatile solution for beauty brands looking for a fully recyclable monomaterial pack. Used in the past as lip balm / lip care only, it is now used with new formulas for scrubs, masks, blush, moisturising, skincare, and makeup in general.

The chico is a sleek new glass bottle with a rounded glass base, a rounded overcap for functionality and design appeal, suited for foundations, serums, or other liquid formulas.

Sustainability & Ethical Sourcing

Capardoni incorporate post-consumer recycled plastics, uses renewable energy, has installed photovoltaic panels, and has achieved ISO 14001 certification. In January 2024, they received an EcoVadis Silver Medal, placing them in the top 15% globally for sustainability. Their emissions reduction targets for 2030 have been validated by the Science Based Targets Initiative (SBTi), aiming to reduce Scope 1 emissions by 42% and maintain zero Scope 2 emissions, while also measuring and reducing Scope 3 emissions. Their Gorgonzola headquarters have achieved energy class A4.

" For years, our company has been integrating post-consumer recycled plastics into its production process. We are convinced that recycling fuels a virtuous supply chain that significantly reduces the consumption of natural resources. The merger between Capardoni and Capsol has enabled us to develop more sustainable packaging solutions than the ones currently available on the market. Examples include the single-material dropper, which is made entirely of PP components that can be disposed of without separation, and the tamper-evident flip-top cap, which preserves the integrity of the product and reduces plastic use by eliminating the need for a seal thanks to its patented anti-unscrewing feature," expresses Filippo Meazza, VP Sales & Marketing, Capardoni.

In an ever-evolving world with trade and tariff restrictions, as well as risks associated with materials and sourcing pressure, sourcing in Italy seems an interesting bet for European companies.